top of page

News

Case Study: Rapid Deployment of Extreme Duty Rotary Valves for Critical Fly Ash Beneficiation

How Delta Ducon Solved a catastrophic Start-Up Failure and Saved a Multi-Million Dollar Process. In the high-stakes world of bulk material handling, equipment failure isn't just an inconvenience—it is a financial hemorrhage. This case study details how Delta Ducon intervened during a critical start-up failure at a major US based fly ash beneficiation plant. When a competitor’s standard rotary valve failed immediately due to the extreme abrasiveness of beneficiated ash, Delta

Matt DelPizzo

6 days ago

Solving the "Angel Hair" Headache at PACK EXPO East

Join SPIRA/flo Pipe (a Delta Ducon, LLC Innovation) right here in our own backyard at PACK EXPO East in Philadelphia! If you’re in packaging production—handling everything from bags and bottles to specialized containers—you’re likely all too familiar with the frustrations of pneumatic conveying for plastic pellets. When using standard smooth-wall piping, excessive friction isn't just a technicality; it’s a productivity killer. It causes pellet breakdown that leads to: Angel h

Matt DelPizzo

Feb 2

Delta Ducon Rotary Valves: Rotary Valve Applications and Benefits

In the demanding world of heavy industry, efficient bulk material handling is not just a convenience - it is a necessity. Rotary valves play a pivotal role in this process, ensuring smooth, controlled flow of materials across various stages of production. Among the many options available, delta ducon rotary valves stand out for their precision engineering and robust performance. Their design and functionality address the critical challenges faced by industries handling powde

John Forbes

Jan 30

Why do Double Dump valves keep failing in CKD applications? (And what we did about it in Texas).

A major cement producer in Texas recently called us with a familiar problem. Their existing Cement Kiln Dust (CKD) dilute phase system was plagued by leakage, inconsistent feed rates, and constant maintenance. The culprit? Double Dump Valves. Double dumps are "batch" style valves. To replicate the continuous flow needed for pneumatic conveying, the gates must cycle rapidly. ❌ Excessive cycling = rapid mechanical wear. ❌ Wear = leak points. ❌ Leakage = plugging and inconsi

Matt DelPizzo

Jan 28

Understanding Delta Ducon Solutions in Material Handling

In the world of heavy industry, efficient material handling is not just a convenience - it is a necessity. The ability to move bulk materials swiftly, safely, and reliably can define the success of an operation. This is where advanced technology and innovative engineering come into play. Among the leaders in this field, Delta Ducon stands out for its commitment to transforming bulk material handling through cutting-edge pneumatic conveying systems and equipment. Their soluti

John Forbes

Jan 23

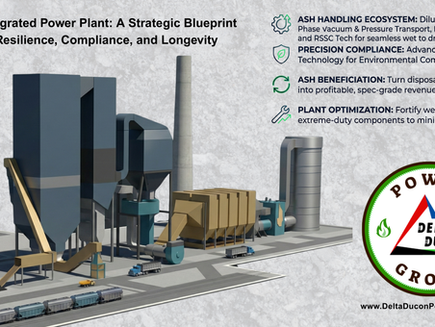

The Integrated Power Plant: A Strategic Blueprint for Resilience, Compliance, and Longevity

Category: Industry Insights / Strategic Planning Most discussion in the power industry focuses on the isolated "pain point of the month"—a failing valve, a new emission target, or a specific conveying bottleneck. While addressing these immediate issues is necessary, the most successful plants view their material handling not as a series of separate problems, but as an interconnected ecosystem. In a sea of articles focusing on single-solution product spotlights, this guide t

Matt DelPizzo

Jan 14

Retrofitting for Success in the Cement Industry

In the high-stakes world of cement production, downtime isn’t just an inconvenience—it’s a massive drain on the bottom line. For decades, the industry relied on heavy, bulky cast-style diverter valves to route abrasive materials through pneumatic conveying lines. However, as production demands increase and maintenance windows shrink, these legacy "monoliths" are becoming a liability. At Delta Ducon , we recently addressed this challenge head-on at a major cement production fa

Matt DelPizzo

Jan 7

Revolutionizing EAF Efficiency: Advanced Injection Technology in the Steel Industry with Delta Ducon and Clyde Pneumatic Conveying

By Matthew DelPizzo, Delta Ducon | Official North American Partner of Clyde Pneumatic Conveying Technology In the high-stakes environment of modern steelmaking, the efficiency of the Electric Arc Furnace (EAF) is paramount. As steel producers face increasing pressure to decarbonize, reduce cycle times, and optimize slag foaming, the precision of material injection has become a critical differentiator. Delta Ducon, a leader in bulk material handling with over a century of

John Forbes

Dec 31, 2025

The Importance of Industrial Conveying Solutions in Heavy Industry

Industrial conveying solutions form the backbone of bulk material handling operations. These systems are designed to transport powders, granules, and other bulk solids efficiently across various stages of production. The right conveying system can significantly reduce downtime, minimize material loss, and improve overall plant safety. For heavy industrial companies, the choice of conveying technology impacts everything from energy consumption to maintenance costs. Pneumatic c

John Forbes

Dec 19, 2025

The Extreme Rotary Valve Advantage: Superior Multiclone Sealing in High-Temp Pulp & Paper Operations

In the Pulp & Paper industry, reliability is the currency of operation. Nowhere is this more evident than in the power and recovery islands of a mill, where equipment is subjected to punishing environments. While Multiclones (multi-cyclone dust collectors) are the industry standard for rugged, first-stage filtration, their efficiency relies heavily on one critical, often overlooked component: the rotary airlock valve at the hopper outlet. For mills struggling with valve failu

Matt DelPizzo

Dec 17, 2025

Stop Wear and Tear: Why PERMA/flo Pipe & Fittings Offer Extreme Abrasion Resistance

Focus: PERMA/flo Pipe & Fittings Goal: Establish Delta Ducon as the expert in piping longevity and demonstrate the technical superiority of your proprietary cast alloy over standard materials. The Pipe Failure Problem in Pneumatic Conveying In systems handling highly abrasive materials like cement, fly ash, or silica, pipe components—especially elbows and bends—are constantly subject to the wearing action of transported solids. Standard carbon steel or even stainless steel pi

John Forbes

Dec 10, 2025

Technical Deep Dive: The Extreme Advantage of PERMA/flo Rotary Valves

Focus: XL/XT Series Rotary Valves (The specialized component the competition lacks) Goal: Educate engineers on why the P-33 Chrome-Iron Alloy is superior to standard surface-hardened valves for abrasive service. Introduction: When "Heavy Duty" Isn't Enough In pneumatic conveying, the rotary valve is the heart of the system, acting as both a feeder and an airlock. For materials like cement, fly ash, and minerals, standard "heavy duty" valves suffer from rapid internal wear, le

John Forbes

Dec 2, 2025

Engineering for Predictable Feed: Why the Dual Rotary Valve System is Required for Consistent Metering

The Unpredictable Challenge of Railcar Unloading In large-scale material transfer operations, achieving a consistent flow rate is critical for system reliability. When unloading material like cement from gravity railcars, engineers face inherent material handling challenges. Railcar hoppers are notoriously shallow-sloped, which can lead to bridging and restricted flow , making conveying rates highly unpredictable. For a high-capacity transfer, a simple, single system is insu

John Forbes

Nov 21, 2025

The True Costs in Abrasive Conveying: Why Cheap Components Cost Millions in the Long Run

An Engineer's Perspective on Truck Unloading Systems for High-Abrasive Materials In high-abrasive industries like cement, mining, and minerals, the cost of a pneumatic conveying system is rarely defined by the initial purchase order. For engineers and plant managers focused on long-term reliability, the focus must shift to Total Cost of Ownership (TCO) , where unscheduled downtime and labor for emergency replacement are the true financial killers. Delta Ducon, with over 100

John Forbes

Nov 21, 2025

Calculating the ROI on Engineered Systems

Why Project Budgeting Must Shift from Price to Predictability In high-volume material handling, especially with challenging products like hot Fly Ash (at 176 degree F and 65 PCF bulk density), the initial capital expenditure is a minor fraction of the true cost of ownership. For a high-capacity transfer system—such as a 300 TPH project—the real financial threats are unscheduled downtime and maintenance labor . Delta Ducon, leveraging a century of expertise and strategic col

John Forbes

Nov 21, 2025

Technical Paper: Engineered Precision and Durability: Mastering High-Abrasive Material Flow with the Delta Ducon 14" XL Extreme Feeder

Abstract In the demanding sectors of cement, mining, minerals, steel, building products, battery and power generation, premature equipment failure due to abrasive wear is the single largest contributor to unscheduled downtime and inflated maintenance budgets. This paper details the specialized engineering, materials science, and operational benefits of the Delta Ducon 14" XL Extreme Feeder (Rotary Feeder/Airlock Assembly) . Built upon decades of proven service, the 14" XL Fe

John Forbes

Nov 4, 2025

Master the Grind: The Essential Guide to Abrasion Mitigation in Pneumatic Conveying Systems

For industries handling materials like fly ash, silica sand, alumina, cement, and crushed minerals , the greatest enemy is not production capacity, but abrasion . The relentless, high-speed scouring of abrasive particles against internal components leads to staggering costs: unscheduled downtime, constant component replacement, and high maintenance labor expenses. This guide details the essential, trending strategies for abrasion mitigation and system protection in pneumatic

John Forbes

Oct 14, 2025

Don't Lose Your Budget: Optimize Your End-of-Year Spending with Delta Ducon

As the fiscal year draws to a close, many industrial sites face a critical challenge: a "use it or lose it" budget . You’ve worked hard to secure funding for CAPEX, Maintenance, Safety, and Environmental projects, and now is the time to ensure that money is spent wisely to benefit your facility for years to come. Instead of rushing to spend your remaining budget on quick fixes that offer short-term relief, the strategic approach is to invest in long-term solutions that boost

John Forbes

Oct 9, 2025

Navigating the Heat: The Critical Role of High-Temperature Rotary Valves in Abrasive Material Handling

In demanding industrial environments, standard valves simply can’t withstand the extreme heat. Processes in industries like cement, power generation, steel, and minerals often require components to operate at temperatures that would cause conventional valves to fail, leading to dangerous leaks, costly downtime, and severe production bottlenecks. This is where high-temperature rotary valves become an indispensable solution, providing a critical airlock and feeding mechanism i

John Forbes

Oct 9, 2025

Unraveling Pneumatic Conveying: Your Go-To Guide from Delta Ducon

Tired of Material Handling Headaches? Let's Talk Pneumatic Conveying! If you're in an industry that moves bulk materials – think powders, granules, pellets, or even chunky stuff – you know the challenges: dust, spills, wear and tear on equipment, and getting materials exactly where they need to go, efficiently and safely. That's where pneumatic conveying comes in. At Delta Ducon, we live and breathe pneumatic conveying, designing systems that solve these exact problems. But

John Forbes

Sep 12, 2025

bottom of page