Replacing you outdated Diverter Valve: Why the Delta Ducon KG Diverter is the only choice

- John Forbes

- Aug 16, 2025

- 5 min read

For industries dealing with abrasive bulk materials like cement, mining ores, minerals, steel byproducts, and power generation fuels, efficient and reliable material handling is paramount. At the heart of many pneumatic conveying systems lies the diverter valve, a critical component responsible for directing the flow of these materials to different destinations. However, many facilities still rely on older style diverter valves that are prone to wear, leakage, and frequent maintenance, leading to costly downtime and reduced operational efficiency. Delta Ducon, with over a century of experience in designing and manufacturing robust material handling solutions for these demanding industries, offers a modern and superior alternative: the KG Diverter.

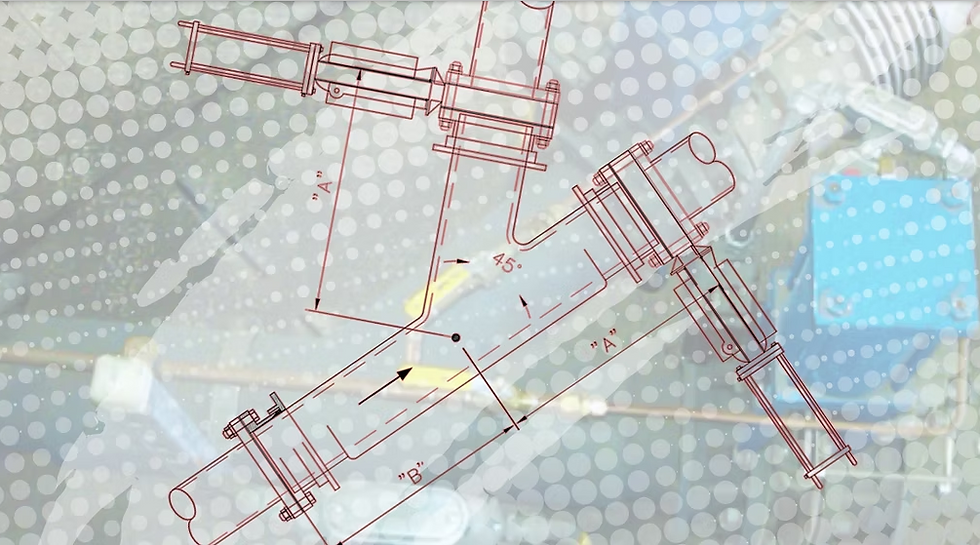

The Delta Ducon KG Diverter represents a significant leap forward in diverter valve technology. Engineered specifically for handling highly abrasive materials, it boasts a design focused on minimizing wear, ensuring tight sealing, and simplifying maintenance. This article will explore the limitations of older style diverter valves and highlight the key advantages of the Delta Ducon KG Diverter, referencing recent successful installations, including a notable 12" valve replacement for a major cement producer.

The Challenges of Older Style Diverter Valves

Traditional diverter valves, often employing flap, plug, or wye-leg designs, can struggle in the face of abrasive materials. Their inherent mechanisms and construction often lead to several common issues:

Excessive Wear: Direct material impingement on moving parts and internal surfaces causes significant wear, particularly in high-velocity conveying systems. This wear leads to reduced lifespan of the valve components, requiring frequent and costly replacements.

Leakage: As internal components wear, achieving a tight seal becomes increasingly difficult. Leakage at the valve can result in material loss, dust emissions, and potential safety hazards, not to mention inefficiencies in the conveying process.

High Maintenance Requirements: The frequent wear and potential for jamming in older designs necessitate regular inspection, lubrication, and part replacement. This translates to significant maintenance labor costs and increased downtime.

Flow Restrictions and Material Degradation: Some older designs can create internal restrictions or turbulent flow patterns that can lead to material degradation, especially with fragile materials, and increased energy consumption.

Difficulty in Automation and Control: Integrating older style valves with modern control systems can be challenging, limiting the potential for automated material routing and process optimization.

These limitations can significantly impact a plant's productivity, profitability, and environmental compliance. Recognizing these challenges, Delta Ducon has focused on developing a diverter valve solution that addresses these shortcomings head-on.

The Delta Ducon KG Diverter: Engineered for Abrasive Service

The Delta Ducon KG Diverter is specifically designed to overcome the limitations of older style valves when handling abrasive bulk solids. Its robust construction and innovative design features contribute to its superior performance and longevity:

Wear-Resistant Construction: The KG Diverter utilizes the Delta Ducon Perma/flo piping.

Sealing options: Our diverter valves feature a robust sealing mechanism designed to provide a tight, dust-tight seal. We offer a variety of sealing options, allowing us to customize the valve to meet the specific requirements of your application and the materials being handled. This ensures optimal performance and prevents leakage in both the active and inactive legs.

Smooth Material Flow: The internal geometry of the KG Diverter is engineered to promote smooth material flow with minimal turbulence. This reduces material degradation across the valve, leading to more efficient conveying.

Low Maintenance Design: With its focus on wear resistance and a simplified design, the KG Diverter requires significantly less maintenance compared to older style valves. This translates to reduced downtime, lower maintenance costs, and increased operational availability.

Adaptability and Customization: The KG Diverter is available in various sizes and configurations to suit different line sizes and application requirements. Delta Ducon engineers can customize the valve to seamlessly integrate with existing or new conveying systems.

Recent Success Story: 12" KG Diverter for a Major Cement Producer

Delta Ducon recently completed a significant project involving the replacement of multiple outdated diverter valves at a major cement production facility. The customer was experiencing frequent failures and leakage with their existing 12" diverter valve, leading to production interruptions and increased maintenance costs.

After a thorough assessment of their needs and operating conditions, Delta Ducon recommended and supplied a 12" KG Diverter. The installation was completed efficiently.

Elimination of Leakage: The robust sealing mechanism of the KG Diverter reduces the material leakage previously experienced, resulting in a cleaner and safer working environment.

Improved Reliability: The wear-resistant design significantly reduces the need for maintenance interventions, leading to increased uptime and production efficiency.

Smooth Material Flow: The optimized internal geometry of the KG Diverter ensures a smooth and uninterrupted flow of cement powder, minimizing any potential for material degradation or flow restrictions.

The successful installation of this 12" KG Diverter is a testament to its capabilities in demanding cement industry applications. The customer is highly satisfied with the performance and reliability of the new valve.

Multiple Ongoing Projects Replacing Older Style Valves

This successful 12" replacement is just one example of the growing trend of companies recognizing the benefits of upgrading their outdated diverter valves with the Delta Ducon KG Diverter. We currently have multiple other ongoing projects across various industries, including mining, minerals processing, and power generation, where older style flap, plug, and wye-leg diverters are being replaced with our advanced KG Diverter technology.

These projects are driven by the desire to:

Reduce maintenance costs and downtime.

Improve operational reliability and efficiency.

Minimize material loss and dust emissions.

Enhance safety and environmental compliance.

The positive feedback and tangible results from these installations further validate the superior performance and value proposition of the Delta Ducon KG Diverter.

Conclusion: Invest in Reliability and Efficiency with Delta Ducon

In industries where the reliable handling of abrasive bulk materials is crucial, the choice of diverter valve can have a significant impact on operational efficiency and profitability. Older style diverter valves often present challenges related to wear, leakage, and maintenance, leading to costly downtime and reduced productivity.

The Delta Ducon KG Diverter offers a modern and robust solution engineered specifically to overcome these limitations. Its wear-resistant construction, positive sealing, smooth flow design, and low maintenance requirements make it the ideal choice for replacing outdated valves in demanding applications.

The recent successful 12" diverter valve replacement for a major cement producer, along with numerous other ongoing replacement projects, underscores the growing recognition of the KG Diverter's superior performance and reliability. By investing in Delta Ducon's KG Diverter, companies can significantly improve their material handling operations, reduce costs, and ensure long-term efficiency.

To learn more about how the Delta Ducon KG Diverter can benefit your operations, visit our KG Diverter product page. Our experienced engineers are ready to assess your specific needs and recommend the optimal solution. Don't let outdated valves continue to impact your productivity – Contact Us Today.

Experience the Delta Ducon difference and modernize your material flow systems for enhanced reliability and efficiency Delta Ducon.